A 2-part spray-applied epoxy coating designed to provide long-term corrosion and chemical resistance to equipment operating in continuous immersion at temperatures up to 140°C (284°F). This solvent-free coating has a long overcoat window and its cold curing mechanism with full in service cure reduces downtime and ensures rapid return of equipment to service. Belzona 1523 is easy to mix and apply using heated airless spray equipment, allowing large areas to be quickly and effectively protected.

Outstanding corrosion protection of high temperature equipment, suitable for continuous immersion in water and hydrocarbon mixtures up to 140°C (284°F)

Excellent chemical resistance against a wide range of chemicals including hydrocarbons and amines

2-coat application without the need for flash blasting between coats

Very light colours allowing easy inspection in dark vessels

Coating applied by heated airless spray for quick application

Application and cure at room temperature – no hot work involved

Solvent-free material allowing it to be safely applied in confined areas

Reduces downtime due to its innovative post-cure mechanism activated at service temperatures – no separate post-cure needed

Withstands steam-out process up to 210°C (410°F) and rapid depressurisation

Excellent adhesion to metal surfaces and high retention of adhesion at elevated temperatures

High temperature epoxy coating for oil and gas production equipment such as separators, flare knock-out vessels and evaporators operating under immersion

Corrosion protection against a variety of chemicals in high temperature equipment including boiler vessels, condensers and heat exchangers

Buy Belzona 1523 in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Belzona in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

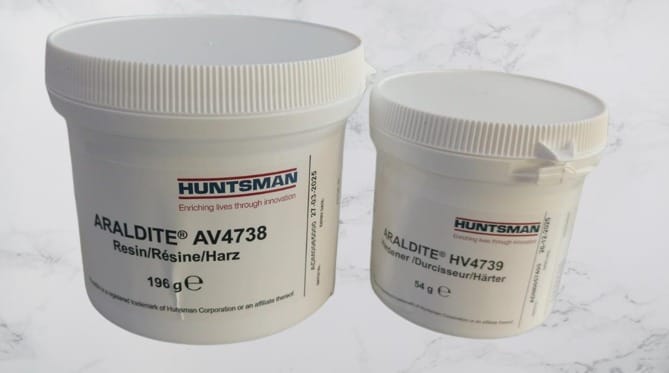

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.