The Belzona Flange Face Forming kit is a unique repair kit developed to aid the flange face forming technology in combating the common problems with mating surfaces of flanged joints such as heat distortion, corrosion and erosion. In conjunction with Belzona 2-part epoxy repair composites such as Belzona 1111 (Super Metal) this flange repair kit provides a complete package solution which is simple to implement and cost-effective. Corrosive action of chemicals, crevice corrosion, bimetallic corrosion and high pressure steam can result in the deterioration and subsequent leakage of flanges. Proven for over 10 years, the Belzona flange face forming technology eliminates the need for conventional cut and weld methods involving hot work and allows for the simple application in emergency situations, especially in areas with limited access such as on offshore platforms. The Belzona Flange Face Forming Kit includes all the equipment required to effectively complete a Belzona flange face forming repair, eliminating the need for spare flanges of multiple sizes. It contains 6 reusable plastic formers to repair the most common flange sizes found in the industry, as well as all other necessary application tools for a quick and easy repair.

Simple to use as all the necessary accessories are in one kit

Each flange face former can be reused hundreds of times

Lightweight allowing easy transportation to emergency situations and areas with limited access

Minimised downtime as the kit eliminates the need for replacement parts

Restoring damaged flange faces

Corrosion resistance for old and new flange faces

Isolation of dissimilar metals from forming corrosion cells

Can be used in conjunction with Belzona nozzle insert and the vessel lining solutions to form a continuous internal lining film terminated outside the process environment

Flanges to repair

ANSI 300# 2” XS, STD, 40, 80, 120, 160, XXS

ANSI 300# 3” XS, STD, 40, 80, 120, 160, XXS

ANSI 300# 4” XS, STD, 40, 80, 120, 160, XXS

Operating pressure and temperature

ANSI 300# rated RF flange faces operating at 120oC 248oF or below

Proven for substrates

Carbon steel, copper nickel, duplex stainless steel, austenitic stainless steel, inconel, monel and cast alloy

Substrate preparation requirements

Belzona recommend SA2.5 surface cleanliness and an average surface profile of 75µm. Power tool cleaning shall comply to SSPS-SP11 producing a bare metal cleaned surface with a minimum 25 micron (1 mil) profile

Typical applications

a.Seawater (firewater, water injection etc.)

b.Open drains

c.AFFF

d.Air

e.Diesel/helicopter fuel

f.Lube/seal oil

g.Glycol

h.Cooling/heating medium

i.Mud and cement

j.Atmospheric vents

Limitations on RF flanges

In hydrocarbon service, Belzona raised face flange repairs have been tested with operating pressures up to 150 bar.

Availability*

Global

Buy Belzona Flange Face Forming Kit in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Belzona in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

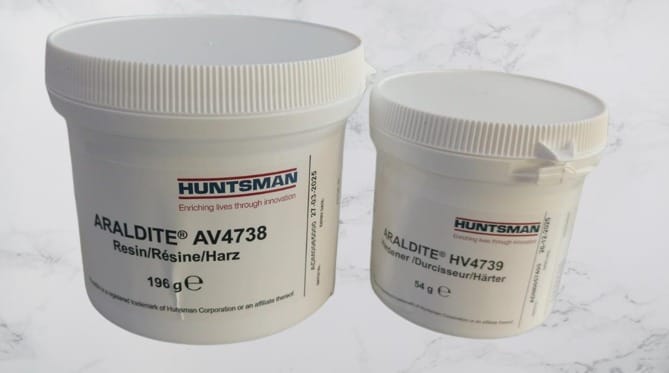

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.