Extreme Heat Resistance – Effective up to 950°C Unmatched Pressure Durability – Handles up to 670 bar Non-Curing & Flexible – Remains elastic; no hardening Quick Application – Use straight from can; apply warm

Birkosit Filling 2000 is a high-performance, single-component sealing paste developed for extreme industrial conditions. It provides reliable, long-term sealing in metal joints exposed to very high temperatures (up to 950°C) and ultra-high pressures (up to 670 bar). Especially effective in turbines, compressors, generators, pumps, and flange joints, this non-curing compound ensures a 100% seal—even in shallow trough-like erosion or corrosion.

Unlike traditional sealants, Filling 2000 requires no mixing, stays flexible, and can be immediately subjected to load after application. It’s ideal for sealing machined or abraded metal surfaces (Ra = 0.8–1.2 µm), compensating damage up to 1.0 mm, without mechanical pre-treatment.

Birkosit Filling 2000 is ideal for:

Sealing metallic butt joints in steam/gas turbines without pre-machining

Sealing metallic butt joints in steam/gas turbines without pre-machining

Repairing and sealing corrosion/erosion ≤ 1.0 mm

Repairing and sealing corrosion/erosion ≤ 1.0 mm

Use on compressors, expanders, generators, and pumps

Use on compressors, expanders, generators, and pumps

Flange joints and screw joints subject to thermal and pressure extremes

Flange joints and screw joints subject to thermal and pressure extremes

High-performance assembly and maintenance tasks in energy & petrochemical plants

High-performance assembly and maintenance tasks in energy & petrochemical plants

Steam and gas turbine sealing

Steam and gas turbine sealing

Oil & gas and refinery installations

Oil & gas and refinery installations

Pump, compressor, and generator maintenance

Pump, compressor, and generator maintenance

High-pressure flange joints

High-pressure flange joints

Petrochemical plant assembly

Petrochemical plant assembly

Power plant overhauls across the GCC

Power plant overhauls across the GCC

Product Name

Birkosit Filling 2000

Pack Size

1 Kg Can

Form

Paste (Viscous at 20°C)

Color

Dark Brown

Cure Type

Non-Curing (Remains Elastic)

Application Method

Putty Knife (Apply warm at 100°C)

Temperature Resistance

Up to 950°C

Pressure Resistance

Up to 670 bar (Screw Joints)

Service Life

10 Years (with correct use)

Storage Life

5 Years (unopened)

Recommended Surface Quality

Ra = 0.8–1.2 µm

Surface Damage Compensation

≤ 1.0 mm

Country of Origin

Germany

Brand

Birkosit / Filling Products Chemotechnische Fabrik e.K.

Extreme Heat Resistance – Effective up to 950°C

Extreme Heat Resistance – Effective up to 950°C

Unmatched Pressure Durability – Handles up to 670 bar

Unmatched Pressure Durability – Handles up to 670 bar

Non-Curing & Flexible – Remains elastic; no hardening

Non-Curing & Flexible – Remains elastic; no hardening

Quick Application – Use straight from can; apply warm

Quick Application – Use straight from can; apply warm

Fills Erosion Damage – Up to 1.0 mm on metal surfaces

Fills Erosion Damage – Up to 1.0 mm on metal surfaces

No Surface Pre-treatment – Saves time and cost

No Surface Pre-treatment – Saves time and cost

Long-Term Use – 10-year performance guarantee

Long-Term Use – 10-year performance guarantee

Ideal for High-Vibration Systems – Maintains seal integrity

Ideal for High-Vibration Systems – Maintains seal integrity

Across Dubai, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait, industries rely on Birkosit Filling 2000 for critical sealing in power plants, turbines, oil rigs, and petrochemical facilities. In these high-demand environments where extreme temperature and pressure are the norm, Filling 2000 provides unmatched sealing without gaskets or complex rework.

Its non-curing nature, elasticity, and heat resistance make it perfect for the harsh climate and operating conditions of the GCC.

Birkosit Filling 2000 is available across Dubai and all major GCC industrial supply networks.

Call: +971 562180452

Call: +971 562180452

Email: sales@hnaenterprises.com for quotes, SDS, or application guides

Email: sales@hnaenterprises.com for quotes, SDS, or application guides

Buy Birkosit Filling 2000 in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Birkosit in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

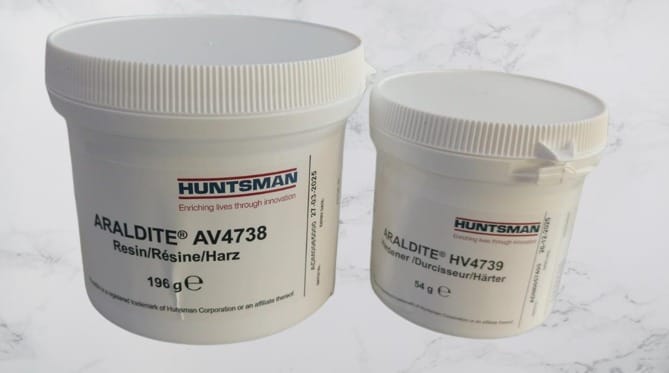

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.