Easy Bar® is a high-temperature kiln lubricant in the form of a solid bar that is inserted between the kiln tire bore and kiln shell. As Easy Bar® melts, the graphite lube and copper distributes precisely to the areas needed. Easy Bar® is your best solution to reduce the wear of the filler bar surface and the riding ring bore while also reducing the scoring of the stop blocks and riding ring.

Save Money, Save Time

How Easy Bar® Reduces Maintenance Costs

1) No Dangerous Flame-Ups

With the highest auto-ignition point in the industry, our bar protects your employees and your equipment from dangerous flame-ups.

2) Fewer Applications

Easy Bar® requires one, weekly application to protect your kiln versus alternative products requiring multiple applications per week.

3) Zero Waste

Our bar’s patented binder quickly evaporates leaving no sticky residue, waste, or harmful chemicals behind for clean-up.

4) Saves Time

Zero mixing or preparation time is needed. Our Easy Bar® comes ready to go, all you have to do is start using it.

5) Protects Equipment Life

Weekly use of Easy Bar® reduces the normal friction and wear of the filler bars. Extending the life of the filler bars maintains the support of the kiln shell and minimizes shell ovality. Maintaining creep can lengthen refractory life. Additionally, reducing friction and wear of the filler bars can minimize weld fractures of the stop blocks and the shell.

6)Lower Labor Costs

With our product, you can cut your lubricant application time to less than one minute per week, effectively lowering labor costs.

Buy Easy Bar | High-Temp Graphite Lubrication Products in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE from HNA Enterprises at best prices!

Buy Easy Bar | High-Temp Graphite Lubrication Products in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Easy in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

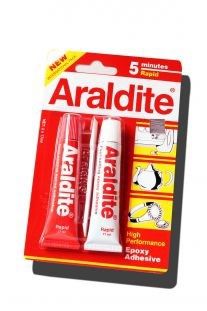

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.