Special lubricating greases for boundary friction conditions and tribo-corrosion MICROLUBE GL 261 grease is a special lubricating grease on a mineral oil base. It also contains special lithium soap and the MICROLUBE additive package, which ensures a wear-free surface finish. Running-in wear is reduced to a minimum. In addition, the MICROLUBE additive package provides protection in the boundary friction regime, thus preventing tribo-corrosion. MICROLUBE GL 261 grease has the capacity to absorb high pressures, and it has good anti-corrosion properties. Content: 400g cartridge Available in 400g cartridge, 1kg can, 25kg bucket, 180kg barrel

Optimum lubrication in the boundary friction regime, thus preventing machine downtime due to tribo-corrosion

Tried-and-tested for many years and approved by OEMs

Longer component life due to special additives, especially with oscillations and micro-movements

Trouble-free operation of machines due to good pumpability in central lubrication systems

MICROLUBE GL 261 grease is particularly suitable for low to medium-speed plain and rolling bearings, and for swivel movements and vibrations.

Linear guides

Serrations, multiple spline shafts

Small gears, e.g. adjustment gears

It is generally suitable for machine elements potentially subject to tribo-corrosion.

MICROLUBE GL 261 grease can be precisely applied by brush, spatula, grease gun, and through centralized lubrication systems.

Chemical composition, thickener

special lithium soap

Chemical composition, type of oil

mineral oil

Lower service temperature

-30 °C / -22 °F

Upper service temperature

140 °C / 284 °F

Color space

yellow

Appearance

almost transparent

Texture

homogeneous

Texture

fibrous

Density at 20 °C

approx. 0.89 g/cm³

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C

approx. 290 mm²/s

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C

approx. 20 mm²/s

Worked penetration, DIN ISO 2137, 25 °C, lower limit value

310 x 0.1 mm

Worked penetration, DIN ISO 2137, 25 °C, upper limit value

340 x 0.1 mm

Speed factor (n x dm)

300 000 mm/min

Flow pressure of lubricating greases, DIN 51805, test temperature: -30 °C

<= 1 400 mbar

Corrosion inhibiting properties of lubricating greases, DIN 51802, (SKF-EMCOR), test duration:

1 week, distilled water

<= 1 corrosion degree

Drop point, DIN ISO 2176

>= 220 °C

Minimum shelf life from the date of manufacture – in a dry, frostfree place and in the unopened

original container, approx.

36 months

Buy Kluber MICROLUBE GL 261 Special lubricating grease 400g in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Kluber In Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here

Buy Kluber MICROLUBE GL 261 Special lubricating grease 400g in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Kluber in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

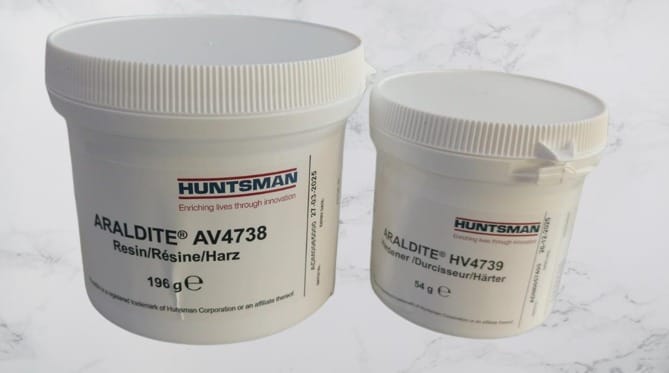

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.