Synthetic heavy-duty grease for long-term lubrication As a manufacturer or operator of modern installations operating at high temperature, you need to protect components subject to high loads and with a high percentage of sliding friction reliably against wear and corrosion, even when they are not relubricated continuously (e.g. sealed rolling bearings). With Klubersynth HBE 94-401 we offer you a lubricating grease based on high-quality synthetic base oil and a special calcium complex soap thickener. This combination enables the formation of a lubricating film with high resistance to mechanical loads providing excellent wear protection. Moreover, Klubersynth HBE 94-401 is resistant to water and has a good sealing effect due to the special thickener component used. Are your components subject to strong oscillations? With its very good antiwear properties, Klubersynth HBE 94-401 meets this challenge too. Content: 1kg can Available in 400g cartridge, 1kg can, 25kg bucket

Very good wear protection,

Excellent corrosion protection

Excellent water resistance

Reduced maintenance costs due to extended relubrication intervals or lifetime lubrication, even at elevated temperatures due to synthetic grease technology

loaded rolling and plain bearings at high temperatures, e.g. in the steel industry.

This special lubricating grease meets the complex requirements of your for-life lubricated components, e.g. in

– support rollers in continuous casting installations

– conveyor roller bearings in continuous furnaces

– support roller bearings in pickling and tin plating

– plain bearings of forging presses

Due to its excellent wear resistance this lubricating grease can also be used for roller bearings in wood pellet presses.

Article number

4295

Chemical composition, type of oil

synthetic hydrocarbon oil

Chemical composition, thickener

calcium complex soap

Lower service temperature

-35 °C / -31 °F

Upper service temperature

160 °C / 320 °F

Colour space

brown

Texture

long-fibred

Texture

homogeneous

Density at 20 °C

approx. 0,93 g/cm³

Flow pressure of lubricating greases, DIN 51805-2, test temperature: -35 °C

<= 1 400 mbar

Worked penetration, DIN ISO 2137, 25 °C, lower limit value

290 x 0,1 mm

Worked penetration, DIN ISO 2137, 25 °C, upper limit value

320 x 0,1 mm

Speed factor (n x dm)

approx. 300 000 mm/min

Shear viscosity at 25 °C, shear rate 300 s-1, equipment: rotational viscometer, lower limit value

4 000 mPas

Shear viscosity at 25°C, shear rate 300 s-1, equipment:rotational viscometer, upper limit value

8 000 mPas

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C

approx. 400 mm²/s

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C

approx. 40 mm²/s

Corrosion inhibiting properties of lubricating greases, DIN 51802, (SKF-EMCOR), test duration: 1 week, distilled water

<= 1 corrosion degree

Oil separation, DIN 51817 N, after 7 d/40 °C

<= 3 % by weight

Drop point, DIN ISO 2176, IP 396

>= 230 °C

Four-ball tester, welding load, DIN 51350 pt. 04

>= 2 800 N

Water resistance, DIN 51807 pt. 01, 3 h/90 °C, rating

0 – 90

Minimum shelf life from the date of manufacture – in a dry, frost-free place and in the unopened original container, approx.

24 months

Buy Klubersynth HBE 94-401 Synthetic heavy-duty long-term lubricant 1kg in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Kluber In Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here

Buy Klubersynth HBE 94-401 Synthetic heavy-duty long-term lubricant 1kg in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Klubersynth in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

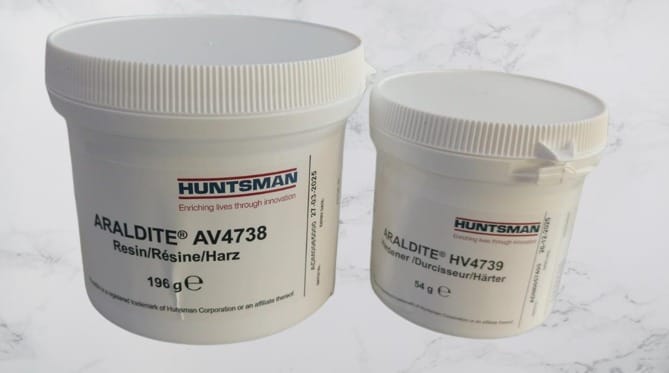

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.