LOCTITE 243 is a medium strength blue threadlocking adhesive that seals and secures metal nuts and bolts to prevent loosening due to shock and vibration. LOCTITE 243 is a general purpose threadlocker that provides a medium strength bond. LOCTITE 243 works on all metals, including passive substrates such as stainless steel, aluminium and plated surfaces. It is proven to be tolerant of minor contamination due to industrial oils, e.g., motor oils, corrosion prevention oils and cutting fluid. Prevents loosening on vibrating assemblies, e.g. pumps, gear boxes or presses Works on all metals, including passive substrates (e.g. stainless steel, aluminium, plated surfaces) Proven to tolerate minor contamination by industrial oils, e.g. engine oils, corrosion prevention oils and cutting fluids Permits disassembly with hand tools for servicing

Loctite 243 | Direction of Use :

1. Bond areas should be clean and free from grease. Clean all surfaces with a Loctite® cleaning solvent and allow to dry.

2. To improve bonding on low energy plastic surfaces, Loctite® Primer may be applied to the bond area. Avoid applying excess Primer. Allow the Primer to dry.

3. LOCTITE® Activator may be used if necessary. Apply it to one bond surface (do not apply activator to the primed surface where Primer is also used). Allow the Activator to dry.

4. Apply adhesive to one of the bond surfaces (do not apply the adhesive to the activated surface). Do not use items like tissue or a brush to spread the adhesive. Assemble the parts within a few seconds. The parts should be accurately located, as the short fixture time leaves little opportunity for adjustment.

5. LOCTITE® Activator can be used to cure fillets of product outside the bond area. Spray or drop the activator on the excess product.

6. Bonds should be held fixed or clamped until adhesive has fixtured.

7. Product should be allowed to develop full strength before subjecting to any service loads (typically 24 to 72 hours after assembly, depending on bond gap, materials and ambient conditions).

Application Method

Dispense System, Manual

Application Temperature

-55.0 – 180.0 °C (-65.0 – 360.0 °F )

Applications

Threadlocking

Breakaway Torque, M10 Steel Nuts/Bolts

~26.0 N·m (230.0 in./lb. )

Colour

Blue

Cure Type

Anaerobic Cure

Fixture Time

10.0 min.

Key Characteristics

Disassembly: Removable, Fluorescent, General Purpose, Oil Tolerant, Primerless, Strength: Medium Strength, Thixotropic

Physical Form

Liquid

Prevail Torque, M10 Steel Nuts/Bolts

5.0 N·m (40.0 in./lb. )

Specific Gravity, @ 23.0 °C

1.08

Substrates

Metal, Metal: Passive Metal

Technology

Acrylic

Viscosity, Speed 20 RPM

2150.0 mPa·s (cP)

Buy Loctite 243 in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Loctite in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

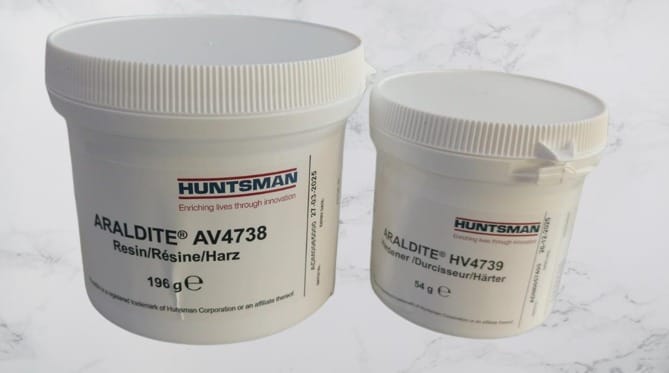

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.