Mobil Jet Oil II is a high-performance aircraft-type gas turbine lubricant formulated with a combination of a highly stable synthetic base fluid and a unique chemical additive package. The combination provides outstanding thermal and oxidative stability to resist deterioration and deposit formation in both the liquid and vapour phases, as well as excellent resistance to foaming. The effective operating range of Mobil Jet Oil II is between -40ºC (-40 ºF) and 204 ºC (400ºF).

Mobil Jet Oil II is a high performance aircraft-type gas turbine lubricant formulated with a combination of a highly stable synthetic base fluid and a unique chemical additive package. The combination provides outstanding thermal and oxidative stability to resist deterioration and deposit formation in both the liquid and vapour phases, as well as excellent resistance to foaming. The effective operating range of Mobil Jet Oil II is between -40ºC (-40 ºF) and 204 ºC(400ºF).

Mobil Jet Oil II is engineered for aircraft gas turbine engines used in commercial and military service requiring MIL-PRF-23699-STD level performance. It also is recommended for aircraft-type gas turbine engines in industrial or marine service applications

Mobil Jet Oil II is formulated to meet the demanding requirements of aircraft-type gas turbines operating over a wide range of severe operating conditions. The product has a high specific heat in order to ensure good heat transfer from oil-cooled engine parts. In extensive laboratory testing and in-flight performance, Mobil Jet Oil II exhibits excellent bulk oil stability at temperatures up to 204ºC (400 ºF). The evaporation rate at these temperatures is low enough to prevent excessive loss of volume. Key features and benefits include:

Features

Advantages and Potential Benefits

Excellent thermal and oxidation stability

Reduces the formation of carbon and sludge deposits

Maintains engine efficiency and extends engine life

Excellent wear and corrosion protection

Extends gear and bearing life Reduces engine maintenance

Retains viscosity and film strength across wide temperature range

Provides effective lubrication at high operating temperatures

Chemically stable

Reduces evaporation losses and lowers oil consumption

Low pour point

Eases start-up in low ambient temperature conditions

Mobil Jet Oil II is recommended for aircraft gas turbine engines of the turbo-jet, turbo-fan, turbo-prop, and turbo-shaft (helicopter) types in commercial and military service. It is also recommended for aircraft-type gas turbine engines used in industrial or marine applications. Mobil Jet Oil II is approved against the Standard Performance (STD) classification of U.S. Military Specification MIL-PRF-23699. It is also compatible with other synthetic gas turbine lubricants meeting MIL-PRF-23699. However, mixing with other products is not recommended because the blend would result in some loss of the performance characteristics of Mobil Jet Oil II. Mobil Jet Oil II is compatible with all metals used in gas turbine construction, as well as with F Rubber (VitonA), H Rubber (Buna N), and silicone seal materials. Mobil Jet Oil II has the following builder approvals *

Engines

Accessories

PRI-QPL-AS5780/SPC

Property

Autogenous-ignition temperature test, deg.C, 30 CFR 35.20

404

Change in Kinematic Viscosity, 72 h @ -40 C, %, ASTM D2532

0.15

Density @ 15 C, kg/l, ASTM D4052

1.0035

Elastomer Compatibility, AMS-3217/4 (72hrs @204C), % swell, FTMS 791-3604

15.6

Elastomer Compatibility,AMS-3217/1(72hr @70C), % swell, FTMS 791-3604

16.4

Evaporation Loss, 6.5 h, 204 C, mass%, ASTM D972(mod)

3

Evaporation Loss, 6.5 hr @ 232 C, 29.5″ Hg, mass %, ASTM D972(mod)

10.9

Evaporation Loss, 6.5 hr @ 232 C, 5.5″ Hg, mass %, ASTM D972(mod)

33.7

Fire Point, °C, ASTM D92

285

Flash Point, Cleveland Open Cup, °C, ASTM D92

270

Foam, Sequence I, Tendency, ml, ASTM D892

8

Foam, Sequence II, Tendency, ml, ASTM D892

10

Foam, Sequence III, Tendency, ml, ASTM D892

8

Kinematic Viscosity @ 100 C, mm2/s, ASTM D445

5.1

Kinematic Viscosity @ 40 C, mm2/s, ASTM D445

27.6

Kinematic Viscosity @ -40 C, mm2/s, ASTM D445

11000

Pour Point, °C, ASTM D5950

-59

Shear Stability, %KV loss, ASTM D2603

0.9

Total Acid Number, mgKOH/g, ARP 5088

0.03

Ryder Gear Load Carrying, % vs ref., FTMS 791-6508

115

Buy Mobil Jet Oil II in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, UAE at best Prices from HNA Enterprises. Ready Stock Available.

Check out our range of Mobil in Dubai, Sharjah, Ajman, Umm al Quwain, Al Ain, Ras al Khaimah, Abu Dhabi, Saudi Arabia, Qatar, Oman, Bahrain by clicking here.

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and toughness. Araldite 2011 Epoxy is suitable for bonding a wide range of materials in common use. The 2011 Epoxy is a versatile adhesive for the craftsman as well most industrial applications. Features: High shear and peel strength Tough and resiliant Good resistance to dynamic loading Bonds a wide variety of materials in common use Various sizes available

Araldite 2014-2 is a two component, room temperature curing, thixotropic paste adhesive of high strength with good environmental and excellent chemical resistance. Features: Grey Paste High Temperature Resistance Gap Filling Various sizes available

Araldite 2015 is a two component, room temperature curing paste adhesive giving a resilient bond. It is thixotropic and non sagging up to 10mm thickness. Features: Toughened paste Ideal for bonding GRP, SMC and dissimilar substrates Gap filling, non-sagging up to 10mm thickness Good resistance to weathering Various sizes available Araldite 2015 200ml, 50ml cartridge or 2kg kit

CHARACTERISTICS: Very high shear and peel strength Extremely tough and resilient Good moisture resistance Bonds a wide variety of materials including metal, wood, rubber, glass fibre reinforced composites and many plastics

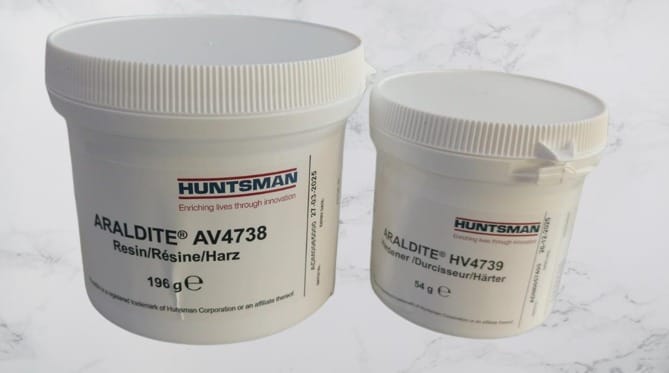

Araldite AV 4738 with Hardener HV 4739 is a two component, ambient temperature curing paste adhesive, which after post-curing either at application or in service, will give bonds with temperature resistance up to 150°C and excellent resistance to common chemicals. It is suitable for bonding a range of metals and polymeric substances such as GRE, GRP, ABS and SMC.

Araldite LY 556 is an epoxy resin that is Anhydride-cured and has low-viscosity. Supplied in various sizes.